Services

Roof Condition Assessments

Evaluating the condition of your existing roof system is the first step to determining what you have to work with. Many times, the service life of a roof can be extended by several years by simply having a qualified roofing contractor make relatively inexpensive repairs or preventive maintenance measures, allowing you time to budget the funds necessary for when a full roof replacement is needed. Conversely, our evaluation may determine that your roof has reached the end of its serviceable life and should be replaced. In either scenario, PRSC’s detailed Roof Condition Assessment (RCA) report, complete with detailed photos, defect descriptions, repair

recommendations, as well as repair and replacement budgets provide you with the information necessary to make decisions that are most advantageous to your business.

Roof System Design and Specification

When it’s time to replace your roof, PRSC provides you the comfort of knowing that you have a teammate who is looking out for your best interests. We will design a roof recover or replacement system that is code compliant and warrantable within the roof system manufacturer’s specifications and guidelines. We ensure that your project uses materials best suited for your building’s function (i.e. restaurant, school, warehouse, etc.) and geographic location, as well as a system that gives you the most return for your budget dollars.

Project Management and Quality Assurance

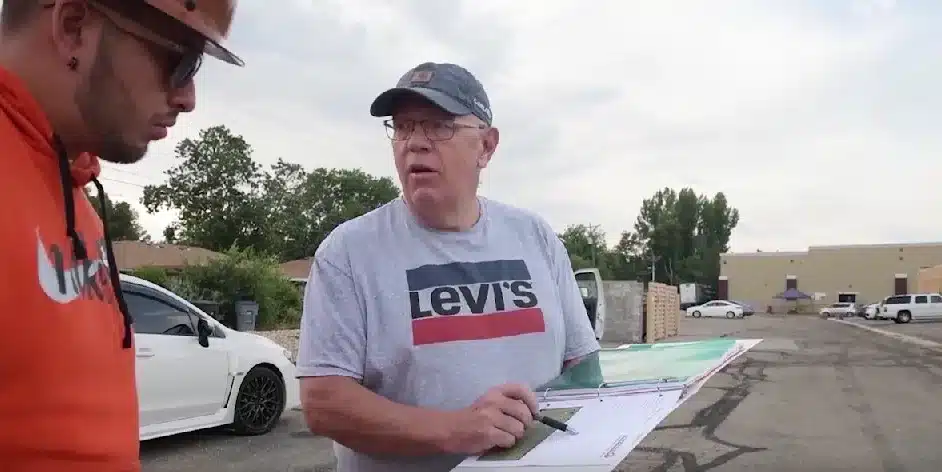

PRSC can also serve as your representative in the preparation and publication of Request for Proposals (RFPs) once you’re ready to find a qualified roofing contractor to do the work. In this service, we will conduct an onsite pre-bid visit with responding contractors and subsequently assist you in evaluating their proposals and determining the most qualified contractor for the job. Once a contractor is selected, we will conduct another onsite pre-construction meeting with the contractor and your facility staff to answer questions and ensure that everyone understands the scope of work before commencing the roof replacement project. Lastly, PRSC offers a service called “Quality Compliance Observation”, where a dedicated quality compliance observer (QCO) is on site during the project (daily or periodically) to ensure quality work is being performed in compliance with the both the manufacturers and our project design specifications.